Embark on a journey through the world of roof insulation materials comparison, where we delve into the characteristics, costs, environmental impact, and performance of various insulation options. Get ready to explore the ins and outs of fiberglass, foam board, spray foam, and cellulose insulation, and discover which one suits your needs best.

In this guide, we break down the essential aspects of each material to help you make an informed decision when it comes to insulating your roof.

Types of Roof Insulation Materials

When it comes to roof insulation materials, there are several options available, each with its own set of characteristics and benefits. Let's take a look at the most common types: fiberglass, foam board, spray foam, and cellulose insulation.

Fiberglass Insulation

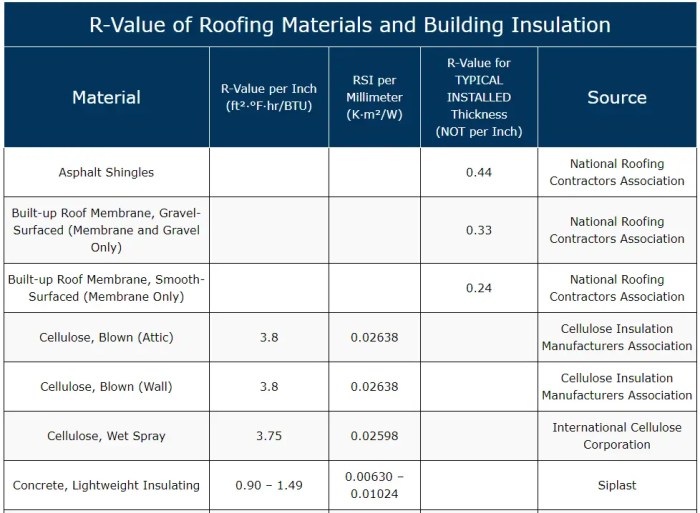

Fiberglass insulation is one of the most popular choices for roof insulation. It is made from tiny glass fibers and comes in batts or rolls. Fiberglass insulation is known for its affordability and ease of installation. It has a good R-value, typically ranging from 2.2 to 2.7 per inch, making it an effective insulator.

However, fiberglass insulation can be itchy to handle during installation.

Foam Board Insulation

Foam board insulation is another common option for roof insulation. It is made from polystyrene, polyisocyanurate, or polyurethane and comes in rigid panels. Foam board insulation has a high R-value, ranging from 4 to 8 per inch, providing excellent energy efficiency.

Installation of foam board insulation requires cutting the panels to fit and securing them in place. It is important to properly seal the seams to prevent air leakage.

Spray Foam Insulation

Spray foam insulation is a versatile option that can fill gaps and holes to provide a tight seal. It is made from a mixture of chemicals that react and expand to create a foam. Spray foam insulation has a high R-value, typically around 6 to 7 per inch, offering superior energy efficiency.

The installation process involves spraying the foam onto the roof deck or underside of the roof. Professional installation is recommended for spray foam insulation.

Cellulose Insulation

Cellulose insulation is made from recycled paper treated with fire-retardant chemicals. It can be blown or sprayed into place, filling gaps and voids effectively. Cellulose insulation has a good R-value, ranging from 3.2 to 3.8 per inch, providing solid energy efficiency.

The installation process for cellulose insulation involves using a blowing machine to fill the attic space or roof cavities.

Cost Comparison

In considering roof insulation materials, cost is a significant factor to take into account. The initial cost of the insulation material, as well as the long-term cost-effectiveness, should be considered when making a decision.

Fiberglass Insulation

Fiberglass insulation is one of the most commonly used and cost-effective insulation materials. The cost of fiberglass insulation typically ranges from $0.40 to $1.20 per square foot.

Foam Board Insulation

Foam board insulation is more expensive than fiberglass, with costs ranging from $0.80 to $2.50 per square foot. However, it provides better insulation and can result in energy savings over time.

Spray Foam Insulation

Spray foam insulation is the most expensive option, with costs ranging from $1.50 to $3.50 per square foot. Despite the higher upfront cost, spray foam insulation can provide superior thermal performance and energy efficiency.

Cellulose Insulation

Cellulose insulation is moderately priced, with costs ranging from $0.60 to $1.50 per square foot. While it may have a higher initial cost than fiberglass, cellulose insulation is environmentally friendly and offers good thermal performance.

Long-Term Cost-Effectiveness

In terms of long-term cost-effectiveness, spray foam insulation may provide the best value due to its superior insulation properties and energy efficiency. While the upfront cost is higher, the potential energy savings over time can offset this initial investment.

Additional Installation Costs

It is important to consider any additional costs associated with the installation of different insulation materials. Factors such as labor costs, equipment rental, and the complexity of the installation process can impact the overall cost of the project. It is recommended to obtain quotes from multiple contractors to compare the total cost of installation for each type of insulation material.

Environmental Impact

Fiberglass, foam board, spray foam, and cellulose insulation each have varying environmental impacts based on their production, installation, and recyclability.

Fiberglass Insulation

Fiberglass insulation is made from recycled glass and sand, making it relatively sustainable. However, the manufacturing process requires a significant amount of energy and produces greenhouse gas emissions. Fiberglass insulation is not biodegradable and can release harmful particles if not properly sealed during installation.

Foam Board Insulation

Foam board insulation is made from petroleum-based materials, which raises concerns about its environmental impact. The manufacturing process generates greenhouse gas emissions, and the insulation itself is not biodegradable. However, some foam boards are recyclable and can be reused in other applications.

Spray Foam Insulation

Spray foam insulation is known for its energy efficiency, but the environmental impact is more significant. The production of spray foam releases potent greenhouse gases, contributing to climate change. Spray foam is not biodegradable, and improper disposal can harm the environment.

However, some companies offer recycling programs for used spray foam.

Cellulose Insulation

Cellulose insulation is made from recycled paper and treated with chemicals for fire resistance. While the production process requires less energy compared to fiberglass or foam board, the transportation of cellulose can increase its carbon footprint. Cellulose insulation is biodegradable and can be recycled or composted at the end of its lifecycle.

Performance and Durability

When it comes to choosing roof insulation materials, considering the performance and durability is crucial for long-term effectiveness and cost-efficiency.

Durability and Lifespan Comparison

- Fiberglass insulation: Fiberglass insulation is known for its durability and can last up to 25-30 years when properly installed and maintained.

- Foam board insulation: Foam board insulation is also durable and can last around 20-30 years with minimal maintenance.

- Spray foam insulation: Spray foam insulation is highly durable and can last 30-50 years or more, making it one of the longest-lasting options.

- Cellulose insulation: Cellulose insulation is less durable compared to other options and may need to be replaced or topped up every 15-20 years.

Performance in Different Climates and Weather Conditions

- Fiberglass insulation: Fiberglass insulation performs well in a variety of climates but may lose effectiveness in extremely cold temperatures.

- Foam board insulation: Foam board insulation is great for all climates and weather conditions, providing consistent performance throughout.

- Spray foam insulation: Spray foam insulation is highly versatile and performs exceptionally well in extreme temperatures and weather conditions.

- Cellulose insulation: Cellulose insulation can be affected by moisture and extreme temperatures, impacting its performance over time.

Maintenance Requirements

- Fiberglass insulation: Fiberglass insulation may require occasional checks for moisture buildup and damage to maintain its effectiveness.

- Foam board insulation: Foam board insulation typically requires minimal maintenance, with occasional checks for any signs of wear or damage.

- Spray foam insulation: Spray foam insulation is relatively low maintenance but may need reapplication or repairs over time to ensure continued performance.

- Cellulose insulation: Cellulose insulation may need to be inspected regularly for moisture issues and may require top-ups or replacements every few years.

Last Word

As we wrap up this discussion on roof insulation materials comparison, remember that choosing the right insulation for your roof is crucial for energy efficiency, cost-effectiveness, and environmental impact. Armed with this knowledge, you can now make a well-informed decision for your roofing needs.

Helpful Answers

What is the most cost-effective roof insulation material?

Fiberglass insulation is generally considered the most cost-effective option due to its affordable initial cost and long-term energy savings.

Which roof insulation material is the most environmentally friendly?

Cellulose insulation is often touted as the most environmentally friendly option as it is made from recycled paper and has minimal environmental impact during production.

How do I determine the right R-value for my roof insulation?

The right R-value for your roof insulation depends on factors like climate, local building codes, and desired energy efficiency. Consult with a professional to determine the optimal R-value for your specific needs.